CARBON STEEL PIPI KABHONI ISINGENASI SIMBA PPIPI CARBON SIMBA ASISINA MUNYOPO

Tsanangudzo

Seamless Simbi Pipe inogadzirwa kubva kusimbi yakatenderedzwa 'billet' inodziiswa nekusundirwa kana kudhonzwa pamusoro pefomu kusvika simbi yaumbwa kuita chubhu isina mhango.Iyo pombi isina musono inozopedzwa kuita dimensional uye mudhuri ukobvu kutsanangurwa muhukuru kubva pa1/8 inch kusvika 32 inch OD.Carbon Steel Seamless Pipes / Tubes Carbon simbi ialloy ine iron uye kabhoni.Iko muzana yekabhoni musimbi inokanganisa kuoma, kusimba kwekusimba uye ductility yekabhoni simbi.Seamless kabhoni simbi pombi kana yakasimba simbi ingot inogadzirwa necapillary chubhu kuburikidza negomba, ipapo kuburikidza nekupisa-kukungurutswa, kutonhora kwakatenderedzwa kana kutonhora kunoitwa.Seamless kabhoni simbi pombi muChina simbi indasitiri ine chinzvimbo chakakosha.Seamless kabhoni simbi pombi zvinhu ichubhu yakatenderera, pombi yekucheka muchina embryos kuti ipfuure nekucheka ingangoita 1 m yekureba isina chinhu, uye inotumirwa neconveyor bhandi choto kupisa.Billet inodyiswa muchoto chekupisa, tembiricha inenge 1200 degrees Celsius.Mafuta ihydrogen kana acetylene.Kudzora tembiricha yevira ndiyo nyaya huru.Round chubhu yakabuda kuti irove nemuchina kuburikidza nemhepo.Kazhinji yakajairika punch ndeye tapered roll perforation muchina, iyo punch yakakwirira yekugadzira kunyatsoita, chigadzirwa mhando, yakakura dhayamita yekuwedzera gomba, inogona kupfeka akasiyana simbi.Perforation, round chubhu yanga iri pamatatu-roll cross rolling, rolling kana extrusion.Yakasvinwa pachubhu mushure mekuita saizi.Kukura nekumhanya-mhanya koni inoboora maburi mubillet kuita chubhu.Pipe dhayamita nesaizi yeguyo kuona kureba kwedhayamita yedhiri.Mushure mepombi kuburikidza nekuyera mushongwe yekutonhora, kutonhora nepfapfaidzo yemvura, simbi mushure mekutonhodza, inofanirwa kutwasanudza.Mushure mebhandi resimbi rinotumirwa nekururamisa simbi yekuyedza muchina (kana kudzvanywa bvunzo) yekuedzwa kwemukati.Kana iyo pombi yemukati inotsemuka, mabhuru uye mamwe matambudziko achaonekwa.Mushure mepombi asiwo kuburikidza nekuomarara kwemhando yekudzora bhuku rekusarudza.Hunhu hwesimbi, kushandiswa kwenhamba dzependi yekupfapfaidza, zvakatemwa, nhamba yekugadzira yakawanda.Nekireni mudura.

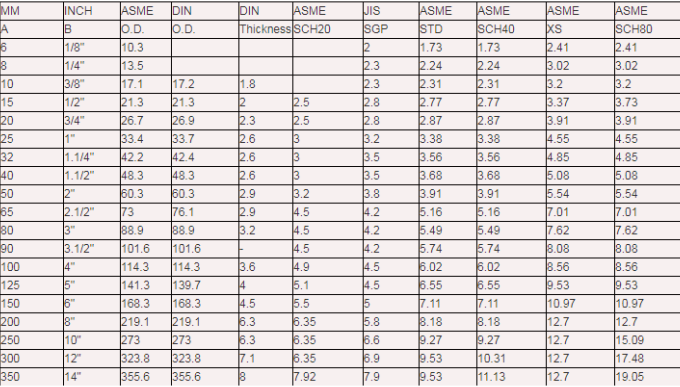

Ukobvu hwemadziro epaipi isina musono

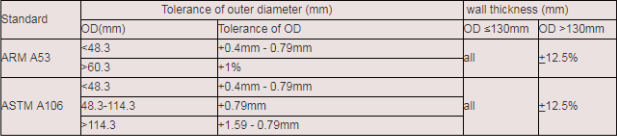

Kushivirira kweOuter Diameter uye Wall ukobvu

Tsanangudzo

| Standard | Tsanangudzo |

| ASTM A179/A179M | Seamless inotonhora inodhonzwa yakaderera alloy simbi yekupisa inotsinhanisa uye condenser machubhu. |

| API 5L | Mutsara pombi. |

| ASTM A53M | Dema & Zinc Yakaputirwa Welded uye Seamless Simbi Pipe. |

| ASTM A106M | Seamless kabhoni simbi pombi nokuda yakakwirira tembiricha basa. |

| ASTM A105M | Carbon simbi forgings yepombi maapplication. |

| ASTM A234M | Piping fittings yeakagadzirwa kabhoni simbi uye alloy simbi yepakati uye yakakwirira tembiricha sevhisi. |

Standard

| Standard | Rudzi rwepombi | Kirasi | Giredhi |

| Purogiramu inonzi SPEC 5L ISO 3183 | SMLS | PLS1 | L245B, L290 X42, L320 X46 , L360 X52, L390 X56, L415 X60, L450 X65, L485 X70 |

| PLS2 | L245N BN, L290N X42N, L320N X46N, L360N X52N, L390N X56N, L415N X60N, L360Q X52Q, L390Q X56Q, L415Q X60Q , L485Q X70Q | ||

| PLS2 Yakasvibira Nzvimbo | L245NS BNS, L290NS X42NS, L320NS X46NS L360NS X52NS, L390NS X56NS, L415NS X60NS, L360QS X52QS, L390QS X56QS, L415QS X60QS L485QS X70QS | ||

| WELD | PLS1 | L245B, L290 X42, L320 X46, L360 X52 L390 X56, L415 X60, L450 X65, L485 X70 | |

| PLS2 | L245M BM, L290M X42M, L320M X46M, L360M X52M, L390M X56M, L415M X60M, L450M X65M, L485M X70M, L555M X80M, |

| Standard | Giredhi |

| ASTM A 53 M | A, B |

| ASTM A 106M | A, B, C |

| JIS G 3454 | STPG 370, STPG 410 |

| JIS G 3455 | STPG370, STPG410, STPG480 |

| JIS G 3456 | STPG370, STPG410, STPG480 |

Giredhi: Kuumbwa Kwekemikari (%):

| Standard | Giredhi | C | Si | Mn | P | S | Ni | Cr | Cu | Mo | V |

| ASTMA 53M | A | ≤0.25 | - | ≤0.95 | ≤0.05 | ≤0.045 | ≤0.40 | ≤0.40 | ≤0.40 | ≤0.15 | ≤0.08 |

| B | ≤0.30 | - | ≤1.20 | ≤0.05 | ≤0.045 | ≤0.40 | ≤0.40 | ≤0.40 | ≤0.15 | ≤0.08 | |

| ASTM A 106M | A | ≤0.25 | ≥0.10 | 0.27-0.93 | ≤0.035 | ≤0.035 | ≤0.40 | ≤0.40 | ≤0.40 | ≤0.15 | ≤0.08 |

| B | ≤0.30 | ≥0.10 | 0.29-1.06 | ≤0.035 | ≤0.035 | ≤0.40 | ≤0.40 | ≤0.40 | ≤0.15 | ≤0.08 | |

| C | ≤0.35 | ≥0.10 | 0.29-1.06 | ≤0.035 | ≤0.035 | ≤0.40 | ≤0.40 | ≤0.40 | ≤0.15 | ≤0.08 | |

| JIS G 3454 | STPG 370 | ≤0.25 | ≤0.35 | 0.30-0.90 | ≤0.040 | ≤0.040 | - | - | - | - | - |

| STPG 410 | ≤0.30 | ≤0.35 | 0.30-1.00 | ≤0.040 | ≤0.040 | - | - | - | - | - | |

| JIS G 3455 | STS 370 | ≤0.25 | 0.10-0.35 | 0.30-1.10 | ≤0.035 | ≤0.035 | - | - | - | - | - |

| STS 410 | ≤0.30 | 0.10-0.35 | 0.30-1.40 | ≤0.035 | ≤0.035 | - | - | - | - | - | |

| STS 480 | ≤0.33 | 0.10-0.35 | 0.30-1.50 | ≤0.035 | ≤0.035 | - | - | - | - | - | |

| JIS G 3456 | STPT 370 | ≤0.25 | 0.10-0.35 | 0.30-0.90 | ≤0.035 | ≤0.035 | - | - | - | - | - |

| STPT 410 | ≤0.30 | 0.10-0.35 | 0.30-1.00 | ≤0.035 | ≤0.035 | - | - | - | - | - | |

| STPT 480 | ≤0.33 | 0.10-0.35 | 0.30-1.00 | ≤0.035 | ≤0.035 | - | - | - | - | - |

Painting & Coating

Kurapa kwepamusoro pepombi yesimbi: Kuti uvandudze hupenyu hwesevhisi yepombi yemafuta, kurapwa kwepamusoro kunowanzoitwa kufambisa kubatanidzwa kwakasimba kwepombi yesimbi uye anticorrosive coating.Nzira dzekugadzira dzakajairwa ndeidzi: kuchenesa, kubvisa midziyo, pickling, kupfura kuputika kunopisa. zvikamu zvina.

1.Kuchenesa Girisi, guruva, lubricant, organic matter yakanamatira pamusoro pepombi yesimbi, kazhinji inoshandisa solvent, emulsion kuchenesa nzvimbo.Zvisinei, ngura, oxide yeganda uye welding slag pamusoro pepombi yesimbi haigoni kubviswa, saka dzimwe nzira dzokurapa dzinodiwa.Tool ngura kubviswa Simbi pombi pamusoro oxide, ngura, welding slag, anogona kushandisa simbi waya bhurasho kuchenesa uye kupukuta pamusoro kurapwa.

2.Tool derusting inogona kukamurwa kuita manual uye simba, manual tool derusting inogona kusvika kuSa 2 level, simba rekushandisa derusting rinogona kusvika kuSa3 level.Kana pamusoro pepombi yesimbi yakasungirirwa neganda rakasimba re oxide, zvingave zvisingakwanisi kubvisa. ngura nerubatsiro rwezvishandiso, saka tinofanira kutsvaga dzimwe nzira.

3.Pickling Kazhinji pickling nzira dzinosanganisira makemikari uye electrolysis.Asi chete kemikari pickling inoshandiswa pombi yekudzivirira ngura.Chemical pickling inogona kuwana imwe dhigirii yehutsanana uye roughness pamusoro pepombi yesimbi, iyo yakakodzera kune inotevera anchor mitsara.Kazhinji se pfuti (jecha) mushure mekugadzirisa zvakare.

4.Kupfurwa kwepfuti yekubvisa ngura.Nemagetsi emagetsi dhiraivha mablades anotenderera, simbi yesimbi, simbi inopfura, chikamu, zvicherwa uye imwe waya inoputika pasi pekuita kwesimba recentrifugal pane simbi pombi yekupfapfaidza uye ejection yakawanda, bvisa zvachose. ngura, oxides uye tsvina kune rumwe rutivi, kune rumwe rutivi, simbi pombi pasi pechiito cheabrasive chisimba chekuita uye friction simba, kuti uwane inodiwa yunifomu roughness.Pakati penzira ina dzokurapa, kupfura kuputika uye derusting inzira yakanaka yekurapa. pombi derusting.Kazhinji, kuputika kwepfuti uye derusting kunonyanya kushandiswa mukati mepamusoro kurapwa kwepombi yesimbi, uye kuputika kwepfuti uye derusting kunonyanya kushandiswa kunze kwepamusoro kurapwa kwesimbi pombi.

Packing&Loading

Pfaya pendi

Kuputirwa nemvura